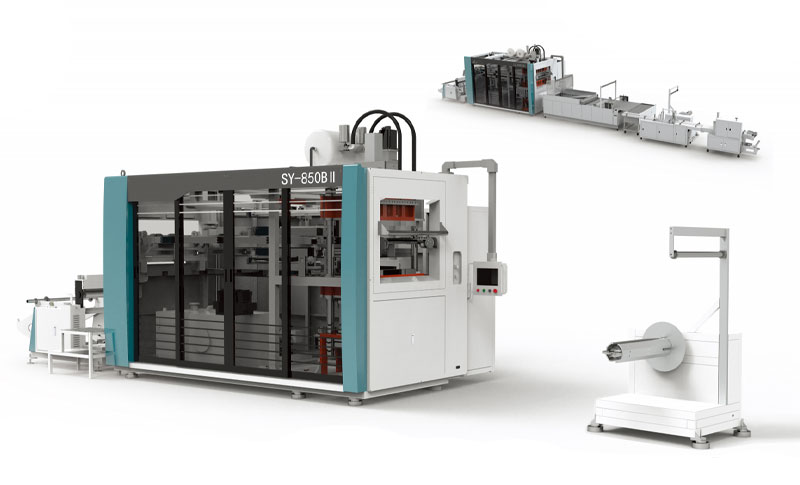

Max.Forming Area: 850/550

Max.Forming Height And Depth: ≤140 mm by robot, ≤180mm by blowing

Max.sheet width: 870

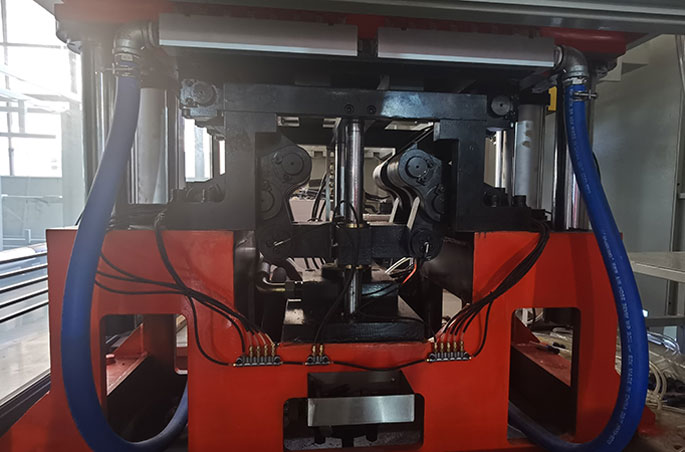

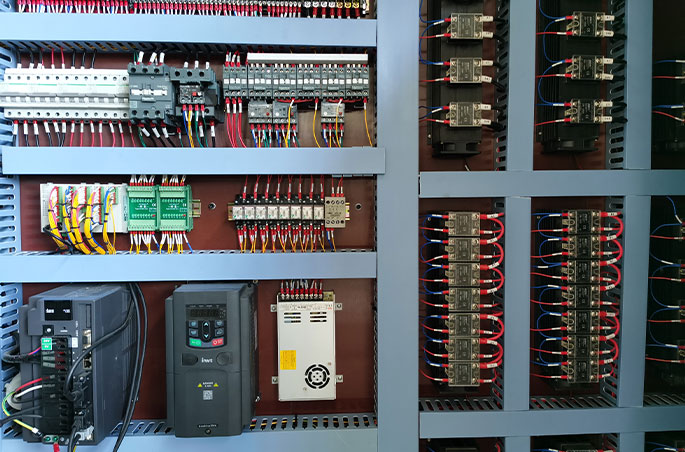

Major Construction Features

Main Technical Parameters

| Model | SY-850B II | SY-850B III |

| Max.Forming Area | 850*550mm | 850*550mm |

| Max.No-Load Speed | 30Cycles/min | 40 Cycles/min |

| Running Pattern | Hydraulic | Servomotor |

| Feeding Driven | Motor With Encode | Servo Motor |

| Stretching Pattern | Servomotor | |

| Sheet Specification | THK:0.2-2mm,W:Max.870mm | |

| Max.Forming Depth,Sample Height | ≦140mm with robot, ≦175mm by blowing |

≦150mm with robot, ≦180mm by blowing |

| Max.Sheet Roll Dia | 1100mm,1T | |

| Electrical Consumption | 90kw/h | 80kw/h |

| Overall Power | 215kw | 215kw |

| Dimension(LxWxH) | L4400*W3350*H3300mm | L4400*W3350*H3300mm |

| Weight | 8T | 8T |

Notes: lf any change of data, we will not notify further

GET A QUOTE