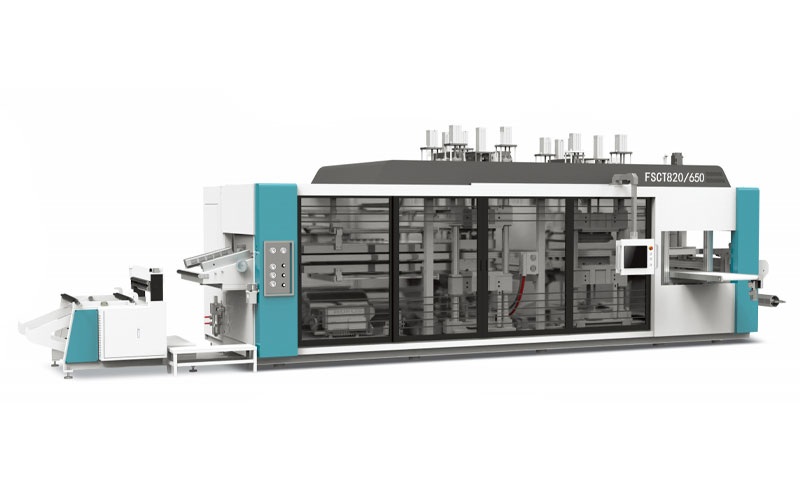

Major Construction Features

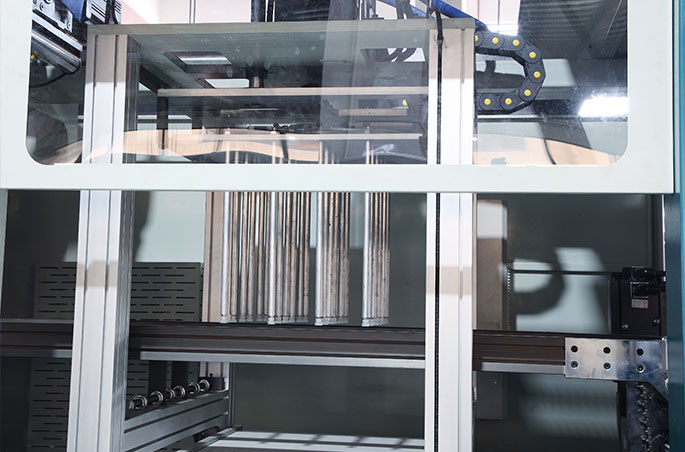

- Fast and accurate temperature control system (error 1 degree), with hot furnace detection material drop and air source ow pressure protection system

- lntelligent operation, the whole machine is equipped with formula storage and automatic adjustment without shutdown

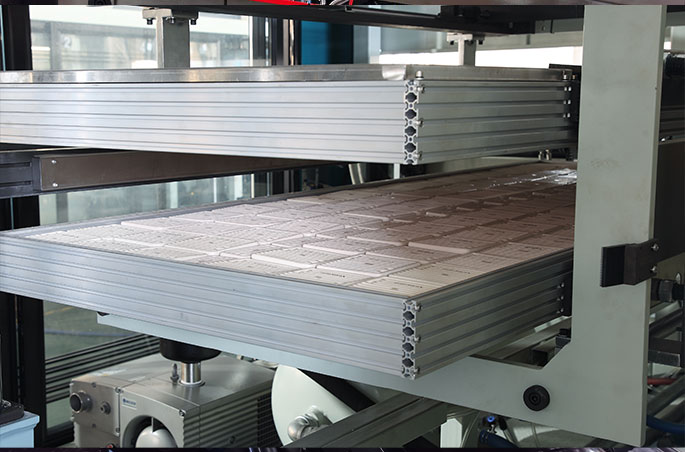

- lt can share molds with models of most wel-known brands at home and abroad, and cooperate with existing production lines

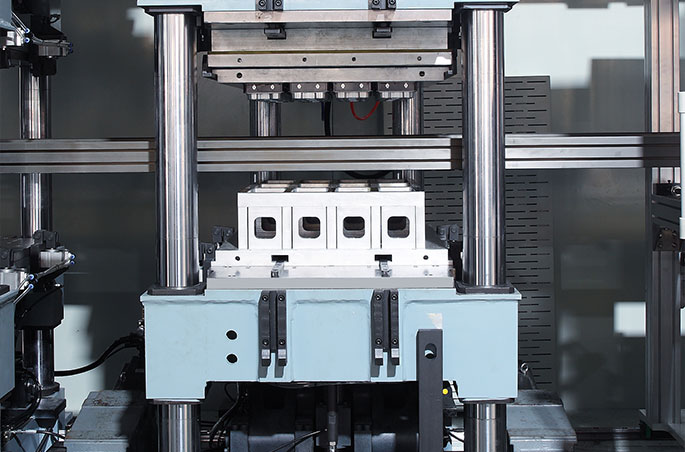

- Fast mold change system, which can facilitate fast, accurate and safe mold change and reduce machine downtime

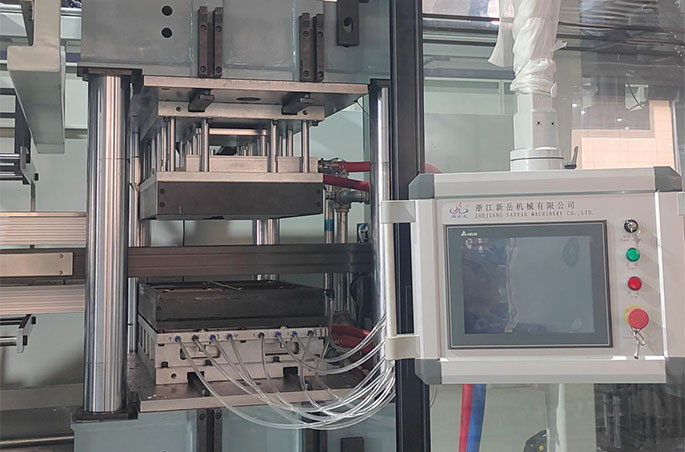

- Under any forming scheme, the clamping frame and plug ass2024-01-08 11:14:122024-01-24 16:44:11ist function can be used alone or at the same time, greatly simplify the mold structure

- Materials with strong shrinkage can adopt the single station in-mold-forming-cuting function to 100% ensure the edge cutting accuracy

- High precision forming and cutting technology to achieve the perfect forming and cutting performance of high-speed control and low wear

- The stacking station can be customized, which simplifies the stacking of complex parts and is convenient to meet furthe production needs

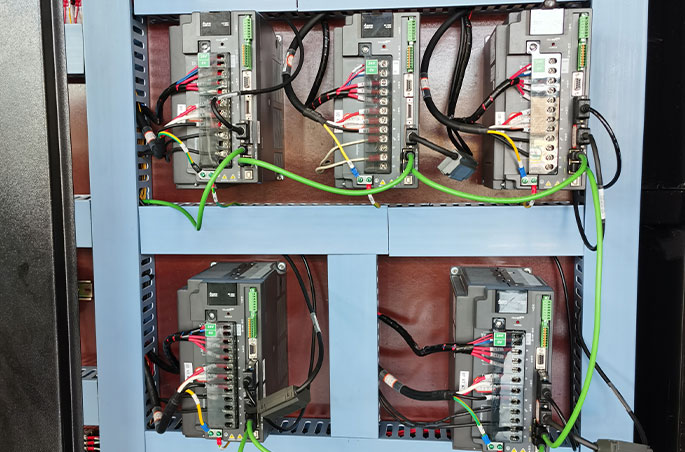

- Optimize the desian of electric cabinet and simplify the machine assembly and wiring installation process

Main Technical Parameters

| Mode |

FSCT820/650-2 |

FSCT820/650-3 |

FSCT820/650-4 |

| Qty of Stations |

2 |

3 |

4 |

| Sheet Material |

PPPS,PET,PVC,HIPS,PLA,OPS,EPS,C-PET,C-PLA,ABS |

| Forming Clamping Force |

750KN |

| Punching Clamping Force |

750KN |

| Max.Forming Area |

820×650mm |

| Max.Pos/Neg Depth |

150/150 |

| Max.Plastic Sheet Width |

860mm |

| Max.Sheet Roll Dia |

1100mm,1T |

| Sheet Thickness Range |

0.15-2mm |

| Max.No-Load Speed |

65 Cycles/min |

| Air Consumption |

4.5m³/min,0.6-0.8Mpa |

| Rated Power |

185KW |

200KW |

215KW |

| Dimension(LxWxH) |

10000×2900×3150mm |

11200×2900×3150mm |

12500×2900×3150mm |

| Weight |

15T |

20T |

25T |