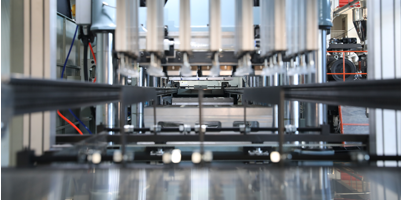

Sayyeah is a trusted global leader in high-end thermoforming technology with over 20 years of experience. We design advanced machines for the efficient mass production of plastic cups and disposable bowls, including drinking, jelly, yogurt, and coffee cups. Our technology processes a wide range of thermoplastics, such as PP, PE, PVC, and PET, handling materials from 0.15mm films to 2mm sheets with precision and consistency.

Versatility: Produces a wide range of cup sizes and shapes, including drinking cups and bowls.

Reliability: Durable, low-maintenance design for long-term performance.

Automation: Efficient, high-capacity operations for seamless production.

High-Volume Production: Fast production capabilities for quick turnaround and large-scale demands.

Max.Forming Area: 600/400

Max.Forming Height And Depth: 80/40

Max.sheet width: 640

Max.Forming Area: 680 / 450

Max.Forming Height And Depth: 140/140

Max.sheet width: 720

Max.Forming Area: 820 / 650

Max.Forming Height And Depth: 150/150

Max.sheet width: 860

Max.Forming Area: 1100 / 850

Max.Forming Height And Depth: 145/125

Max.sheet width: 1130

Thermoforming is a manufacturing process where a thermoplastic sheet is heated until pliable, typically using infrared or convection heaters with precise temperature control based on the plastic type. Once heated, it is formed into a 3D shape either by vacuum forming, which uses a vacuum to draw the softened sheet into a mold cavity, or pressure forming that employs positive air pressure for more detailed and accurate shaping. After forming, the plastic is cooled, often with cooling fans or coolant in the mold, with the cooling rate affecting the final product's quality. It has wide - ranging applications, from creating blister packs in packaging, to manufacturing interior components in the automotive industry and food trays in the food service field, being a crucial and versatile method for producing complex plastic items.

Thermoforming offers several advantages, making it a highly cost-effective and efficient process for producing large-scale, thin-walled products. It allows for the creation of complex shapes with intricate details, making it versatile in producing a wide range of designs and sizes. With relatively low tooling costs and shorter production cycles, thermoforming is well-suited for mass production, enabling businesses to quickly bring products to market. Additionally, it is material-efficient, reducing waste and supporting sustainability. The process uses relatively low pressure and temperatures, further enhancing its cost-effectiveness compared to other forming methods.

Yes, Sayeah offers thermoforming systems worldwide. Through our extensive global distribution network, we ensure that our state-of-the-art thermoforming equipment is accessible to customers across different regions. Sayeah is committed to providing high-quality thermoforming solutions tailored to meet the needs of diverse industries. Our worldwide presence allows us to deliver reliable support and services, ensuring that customers receive optimal performance from our systems no matter where they are located.

The thickness of the material used for thermoforming can vary based on the specific application and requirements. It can range from thin films of a few micrometers to thicker sheets of several millimeters.

A wide range of plastics can be thermoformed, including polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), acrylonitrile butadiene styrene (ABS), and polyethylene terephthalate (PET), among others. The selection of plastic material depends on factors such as the required durability, heat resistance, flexibility, and the specific application needs of the product being created. Each plastic offers unique characteristics, making it suitable for different industries and purposes.

Yes, the cooling speed can significantly impact production efficiency. A fast and precise cooling system helps reduce cycle times, allowing for quicker mold cooling and faster product turnaround. This improves overall production throughput while maintaining high-quality results.The SAYEAH Multi-Station Thermoforming Machine features a fast and accurate temperature control system, capable of reaching the set temperature within 10 minutes.

GET A QUOTE